Over the years, Mountain Soles and Outdoor Threads has fine-tuned their structure and practices in response to the needs of an ever-changing industry. Here are some insights into how these repairers continue to thrive.

For the origin-story hungry among us, the precise history of Mountain Soles and Outdoor Threads can be found on their website. Current Mountain Soles owner Matt Menely took on first a resoling business, then a sewing operation, merging the two under one name. Mountain Soles occupied first one garage, then two, then a retail space, then not – a series of strategic moves leading to the business’s current iteration: a bright, cheery, basement shop with sewing machines cozied side-to-side and an impressive number of neatly-labeled drawers.

Samples of the impressive organization on display in the Mountain Soles shop.

Every Monday, Menely drives to local REI and Patagonia businesses, as well as a post-office box for mailed-in items, retrieving outdoor gear to repair. He and his small team perform repairs in-house. Their turnaround time can fluctuate seasonally, but is always clearly listed on their website. One thing is certain: their services are in year-round demand.

Throughout its existence, Mountain Soles has adapted to suit the varying needs of its employees and customers. There’s no neat how-to list or precise formula for how any business survives and flourishes through the fluctuations of industry and passage of time. However, the manner in which Mountain Soles is forever finding their place in the world gestures toward larger lessons that can perhaps be relevant to other repair businesses seeking to do the same.

During Portland Repair Finder’s visit to his shop, Menely shared some of the Mountain Soles strategies that have helped them achieve continued success.

Matt Menely, owner of Mountain Soles and Outdoor Threads.

Pinpoint the style of customer communication that works best for everyone

The idea of a repair shop can hearken a bygone sense of business: a folksy storefront, a greeting counter, and a long, detailed conversation about the specific needs of each individual repair. While that is still the reality for many repair shops in Portland, in industries from shoes to computers, Menely has learned that this type of customer intake is not conducive or efficient for the Mountain Soles business model. When they operated out of the retail space, Menely found that the unscheduled walk-in traffic interrupted his repair work to the degree that he was staying hours after close to finish projects he had to put aside again and again during the day.

Moving from a storefront to a non-retail location was motivated in part by ever-rising rent, but also conferred the very real benefit of allowing Menely and his employees to manage the workflow on complicated repair projects, allowing them to work uninterrupted through a series of steps that require focused concentration.

However, Menely is aware that availability and transparency are vital aspects for any customers putting their faith into a business and its work.

“We put a ton of time and energy into the website. We have a video on there, we’ve put a lot of pictures up. Customers can go there and really quickly understand what they’re getting and what the repair’s going to look like,” Menely said. “And if someone emails us, I’m super responsive. I’ll try to respond within 24 hours if people have questions about a repair.”

In offering as much relevant information as possible up front on their website, and by scheduling regular communication check-ins around their repairing workflow, Mountain Soles is able to operate as efficiently as possible while still meeting customer needs.

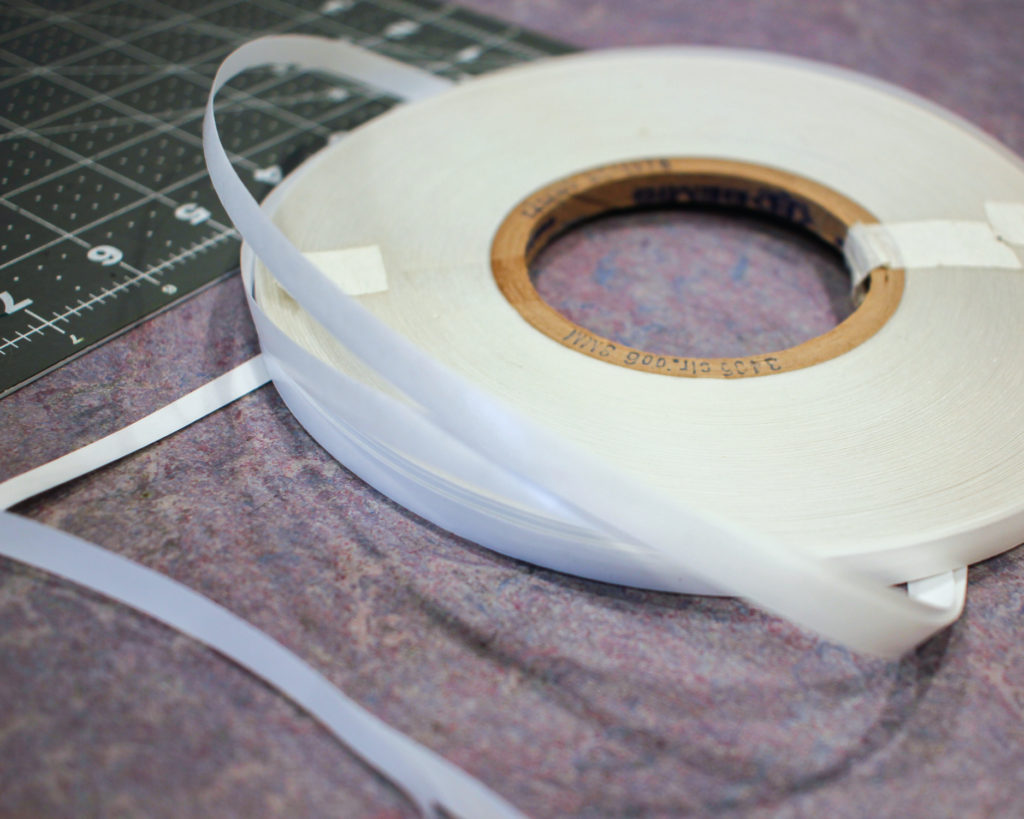

Inventory for potential repairs.

Learn the dimensions of your niche

Some repair entrepreneurs might be best suited to success by learning an array of basic skills, being able to do “a little bit of everything,” and/or selling new or refurbished inventory. Others might hone a singular specialization, mastering a unique, in-demand expertise. Finding the width and depth of work that will support a repair business, without spreading it too thin or pigeonholing it too narrowly, is crucial to sustained success.

When Menely purchased Mountain Soles in 1999, the entire business was shoe repair – hiking boots, climbing shoes, and the like. After merging with a sewing business in 2002 and broadening their repair capacity to outdoor gear and apparel, Mountain Soles did it all until the decision to move yet again, to a non-retail location. Due to space restraints, the toxicity of resoling shoes, and the difficulty of training and retaining shoe-skilled workers, Menely decided to sell off the shoe repair inventory and equipment.

Today, Mountain Soles still repairs snowshoes, through factory-authorized relationships with snowshoe brands Atlas and Tubbs. They retain the ability to do footwear-grade stitching, hardware, and zippers, and repair cross-country ski boots that Menely says are shipped to them from “all over the world.” They also have earned a reputation for premium cycling gear repairs, and receive mailed-in cycling gear on a regular basis. These specialties help supplement their regular general gear pickups to ensure a steady stream of business year-round.

Learning what business is valuable for their setup and what business they can afford to let go of has been an important part of Mountain Soles’ success.

Mountain Soles employees busy repairing.

Embrace experimentation and its inevitable errors

Until repair is welcomed into the fold of the design process for consumer goods, and until repair procedure is an integral consideration in an item’s manufacture, repair work will necessarily be a response to product designs that are indifferent to facilitating repair.

“Designers aren’t making things with repairability in mind; they’re just thinking about things that look cool or that can be manufactured through automated processes,” Menely said. “We’ve had to evolve how and what we’re willing to repair. For instance, laminating. On these new down jackets, they’re laminating instead of stitching the baffles. If you throw that in the dryer, which you need to do with down jackets, and it heats up enough, all that glue comes undone inside.”

While foundational skills of any given repair industry are critical and largely unchanging, a creative approach to repair will also be necessary, in order to adapt to new methods of design and manufacture. The trend in outdoor gear is toward items that are lighter and smaller, which can affect the overall repairability of an item, or the amount of time and energy required for any given repair.

A willingness to engage with ongoing trial and error using new materials and equipment (but never, Menely was quick to stress, experimenting on any gear submitted by a customer) is required from any repair operation hoping to offer consistently reliable and relevant repairs.

One of the many materials necessary for varying repairs.

This is only a snapshot of all the radical practices Mountain Soles employs. While they don’t have a physical location to visit, their comprehensive website is a pleasure to explore. If you’ve got some gear in need of repairing, you can contact them through their website, or bring in your gear to a Portland-area store. Learn more about local gear dropoff here.